Frequently Asked Questions

1. What is a woven patch?

Woven patch is a badge or patch made using weaving technology. Unlike traditional embroidery, woven patches are woven on a loom using fine threads, which can achieve higher details and clarity. They are often used on items such as clothing, backpacks, hats, etc. to increase brand recognition and decorative effects.

2. What is the difference between woven patch and embroidery?

The main difference between woven patches and embroidery lies in the production process and effect. Woven patches are woven on a loom using fine threads, which can achieve finer details and higher clarity, and the surface is smooth and without bumps. Embroidery, on the other hand, is sewing patterns on existing fabrics, using thicker threads, and the patterns have a three-dimensional feel but the details are not as fine as woven labels.

3. What size can a woven patch be?

The size can be customized according to demand, usually up to 7 inches (about 17.78 cm). We have different size restrictions, and the specific size needs to be confirmed with us.

4. Do you have color limits for the woven patch?

Woven patches have relatively few color limits, and in theory, multiple color combinations can be achieved. We can support more than 10 colors, or even more. Complex patterns and gradient colors can also be achieved through special weaving techniques.

5. What is the minimum order quantity?

We do not have minimum order quantity. Whether it is 1pcs, 10pcs, or 100pcs, we can make them for you.

6. How long is the production cycle of woven patches?

The production cycle is usually 8-12 working days, depending on the order volume and complexity. If expedited production is required, it can be negotiated with us.

7. How durable are woven patches?

Woven patches are very durable because they are woven from fine threads rather than simply sewn onto fabric. This makes the woven patch less likely to fade, wear or fall off, and it can maintain good condition even after multiple washes.

8. What are the application scopes of woven patch?

Woven patches are widely used in various scenarios, including clothing (such as T-shirts, jackets, hats), backpacks, outdoor equipment, uniforms, work clothes, sports equipment, etc. They can not only increase the recognition of the brand, but also serve as decorative elements to enhance the overall appearance of the product.

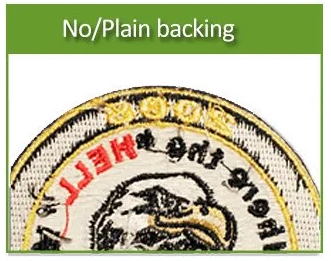

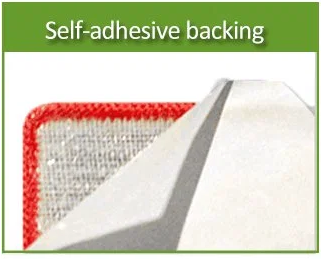

9. What are the price factors of woven patch?

The price is affected by many factors, including order quantity, size, number of colors, complexity, back treatment, etc. Generally, the larger the order quantity, the lower the unit price; the more complex the pattern, the higher the price.

10. What are the cleaning and maintenance methods of woven patch?

Woven patches are very easy to clean and maintain. In general, they can be washed normally with clothes and avoid high-temperature ironing. If special cleaning is required, they can be gently wiped with a damp cloth and then dried naturally. Avoid using bleach or other strong corrosive detergents.

11. Can woven patch achieve gradient color effects?

Yes, they can achieve gradient color effects through special weaving technology. Gradient colors can make the pattern look more vivid and three-dimensional, increasing visual appeal.