Freedom of shape: Woven patches are not limited by shape, whether it is round, square or special-shaped design, it can be easily realized.

Flexible size: From mini size to large-area badges up to 7 inches (about 18 cm), it meets the needs of different scenarios.

Extreme details: Woven patches are particularly good at handling subtle details, even very small text can maintain high readability and achieve almost photo-level clarity.

Wide application: Whether it is a clothing brand logo, team patch, club logo or personal collection, woven patches are one of the best choices to show personality and quality.

Customization Backing Options

When customizing woven patches, choosing the right backing is essential to ensure proper use and long-term durability. Here are six common backing options, each with its own unique advantages and applicable scenarios, to help you make the best choice based on your actual needs.

No/Plain Backing

If you plan to sew a woven patch to clothing, then choosing no backing is the most direct way. This method provides the most flexibility, allowing you to adjust the position as needed.

Also, it is the lowest cost, suitable for situations where permanent fixation is required, will not affect the overall appearance of the woven patch.

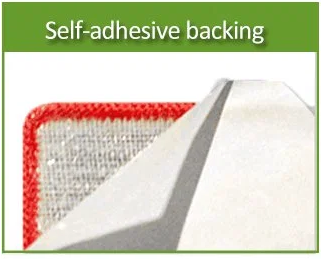

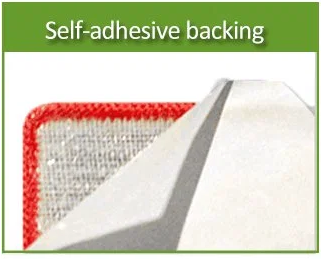

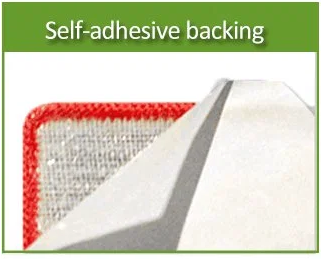

Self-Adhesive Backing

It is suitable for hard surfaces or items that are not suitable for needle and thread fixing, such as plastic, wood, etc.

Also, it is peel and stick, no additional tools required, especially suitable for temporary display or decorative purposes.

Iron On Backing

For those who want to quickly and easily fix woven patch to fabrics, iron-on backing is a good solution. It is a simple and quick operation, just heats with an iron to firmly adhere and suitable for non-permanent or temporary applications.

Self-adhesive Backing

When the position of the woven patch needs to be changed frequently, it provides great convenience. It is strong detachability, easy to install and remove, suitable for uniforms, hats and other places where the logo needs to be changed regularly.

Pin On Backing

It is suitable for any occasion where you need to fix quickly but don’t want to attach it permanently. Simple and easy to use, can be used on almost any type of clothing, easy to carry and display.

Different Fabric Backing

Add an extra layer of protection to woven labels to improve comfort and durability. You can choose a color or texture that matches the woven label to enhance the overall aesthetics, suitable for clothing that comes into direct contact with the skin.

Customization Border Options

Merrow Border

This is a classic overlocking technique that uses a special sewing machine to sew along the edge of the woven patch to form a tight circle of stitches to prevent the edge from unraveling. Merrow border can effectively prevent the edge of the woven patch from fraying and unthreading, especially for occasions where it needs to be used for a long time. It gives a classic and neat feeling and is suitable for woven patches of various materials and thicknesses, especially for woven labels with heavier or complex structures.

Laser Border

It is a technology that uses a high-precision laser beam to accurately cut woven patch, which can achieve very fine and smooth edges. Laser cutting can achieve millimeter-level accuracy, ensuring that every detail is perfectly presented. The cut edge is very clean, without extra threads or burrs, making the woven label look more delicate. This is more suitable for designs with complex or irregular shapes, and can easily handle curves and sharp corners.

Hot Cut Border

It is to melt the fibers at the edge of the woven patch at high temperature, so that it quickly solidifies to form a smooth edge. This method is particularly suitable for synthetic fiber materials. Hot trimming can effectively prevent the edge fibers from loosening and reduce the risk of de-threading. Compared with other methods, hot trimming is simple to operate and has low cost. It is suitable for mass production and can quickly complete the edge processing of a large number of woven patches.

Many customers will hesitate whether they should choose woven patch when choosing patches. In fact, woven patch have several significant advantages that make them ideal for many applications. The following are four main advantages to help you better understand their unique charm.

1. Higher accuracy

Woven patches are woven using fine threads and can capture every detail in the design. This means that even complex patterns and small text can be reproduced clearly and accurately. For those designs that contain a lot of detail or require high resolution, woven patches offer unparalleled clarity and precision.

2. Thinner wires

Compared with embroidered patches, woven patches use thinner threads, which makes the patch itself thinner and softer. Such characteristics make it more suitable for applications in light fabrics or situations that require close-fitting wear. Due to the thin nature of the woven patch, the wearer can barely feel the presence of the patch, thereby improving comfort.

3. 100% full coverage

All woven patches have 100% coverage, which means the entire patch area will be completely covered by the wire without any gaps or gaps. 100% coverage ensures a uniform and consistent surface of the patch, allowing it to maintain a perfect appearance no matter which angle it is viewed from.

4. Clear small letters

Woven marking technology is particularly suitable for processing small letters and fine text. Even very small fonts maintain a high degree of clarity and readability. Whether it is a brand logo, team name or personal signature, woven patches can ensure that this information is presented in a professional and clear way, enhancing the overall sense of professionalism and quality.

Other Popular Patches We Also Make

PVC Patch

Embroidery Patch

Chenille Patch

Chenille Patch

Design Your Woven Patch Now!

AQ PINS is a leader in custom woven patches with over 15+years of experience. Unlike other companies, we welcome orders of all sizes and are flexible with custom woven patch requirements.

High Quality Guarantee: We are committed to providing the highest quality woven patches to every customer.

Top Customer Service: Our customer service team is always ready to support you, answer your questions and ensure your order goes smoothly.

Most Competitive Pricing: We offer the best pricing in the industry to ensure you get the best value for your money.

Fast Production: We have an efficient production process to complete your order in a short time.

Satisfaction Guarantee: If you are not satisfied with the woven patch you purchased, we will immediately refund the full amount or remake your order for free without any conditions.

Transparent Quotation: The first step is to contact us, we will provide you a free quotation with your design for your review.

Digital Archiving: We save all digital samples and design specifications for you, ensuring that your patches maintain consistent high quality and appearance every time you reorder.